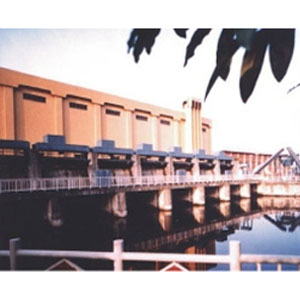

Cable operated bar screen

| Item No.: | 3BS & 2BS |

Supplier Details

Country: Taiwan

City: New Taipei City 242

Address: 8F.,No.354, Huacheng Rd.,Xinzhuang Dist

TEL: +886-2-22769961

Fax: +886-2-22769962

Online Showroom:

37 Products

The cable operated bar screen is full automatically cleaning equipment. It can be used in the inlet channel of pumping station, wastewater treatment plant, power plant and desalination plant for the floating matters screening or bottom accumulation removal.

Function

The rake is traveled in lateral guide rails, by suspension on 3 cables-two for lifting/descending one for opening/closing-the rake can be brought into operation at any depth.

On downward travel, the rake runs in open position within the guide rails. After reached the channel bottom or floating layer the rake movement is reversed by the automatic control of the cable slack sensor; closed the rake travels upward with the trapped screenings.

Above discharge chute, the screenings are discharged by wiper into a cart or onto belt conveyor. The rest position of the rake is above discharge chute.

Design

The screen is designed for a specific water level diffence ( normally 1M WG=10000N/M2). All structural steel parts, grid bars, supports, drive unit etc are designed with sufficient strength.

Basic design

A.Vertical or inclined (90° ~75°)

B.Fixed on concrete channel (By other)

C.Changeable grid sections

D.Channel width 1M to 6M

E.Mechanical Wiper

Installation Options

Function

The rake is traveled in lateral guide rails, by suspension on 3 cables-two for lifting/descending one for opening/closing-the rake can be brought into operation at any depth.

On downward travel, the rake runs in open position within the guide rails. After reached the channel bottom or floating layer the rake movement is reversed by the automatic control of the cable slack sensor; closed the rake travels upward with the trapped screenings.

Above discharge chute, the screenings are discharged by wiper into a cart or onto belt conveyor. The rest position of the rake is above discharge chute.

Design

The screen is designed for a specific water level diffence ( normally 1M WG=10000N/M2). All structural steel parts, grid bars, supports, drive unit etc are designed with sufficient strength.

Basic design

A.Vertical or inclined (90° ~75°)

B.Fixed on concrete channel (By other)

C.Changeable grid sections

D.Channel width 1M to 6M

E.Mechanical Wiper

Installation Options

English

English

Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia