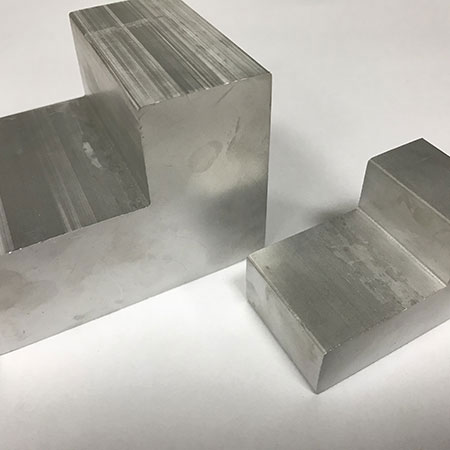

Aluminum Alloy 3003

| Item No.: | 3xxx and 5xxx Work Hardening Aluminum Alloy |

Supplier Details

Country: Taiwan

City: Tainan City 710, Taiwan

Address: No.28, Xinggong Rd., Yongkang Dist.

TEL: +886-6-2335308

Fax: +886-6-2326904

Online Showroom:

31 Products

Aluminum Angle Bar

Dimensions: mm (Millimeter)

OD=Out Side Diameter

t=Wall Thickness

Extrusion --Cross Section Area: 100mm2~10000mm2) Following by EN 755, ASTM B221M

3003 aluminum alloy is the most widely used aluminum alloy. Added manganese increases tensile strength. Used for drawing, spinning, fuel tanks and sheet metal work. This alloy is non-heat treatable, and is corrosion resistant. 5052 aluminum alloy is the highest strength alloy of the non-heat treatable grades. It has good resistance to marine atmosphere and salt water corrosion. With excellent workability it can be easily drawn and formed into intricate shapes.

Dimensions: mm (Millimeter)

OD=Out Side Diameter

t=Wall Thickness

Extrusion --Cross Section Area: 100mm2~10000mm2) Following by EN 755, ASTM B221M

- Material: 3xxx, 5xxx,

- Temper: F, O

- Type: Extrusion

- Application: Aerospace, Automobile, Marine, anti-corrosion

- Products: Pressure Vessels, Truck/Trailer parts, Chemical and Food Equipment, Storage tanks, Home appliances, Gasoline Bottle of Aircraft, Welding Materials, Boat and Ship parts

- Prompt delivery time: 25~35 working days (depends on the difficulty of procedure, quantity, and specific requirements from customer)

- Sizes and designs are all customize

- Origin: Taiwan

3003 aluminum alloy is the most widely used aluminum alloy. Added manganese increases tensile strength. Used for drawing, spinning, fuel tanks and sheet metal work. This alloy is non-heat treatable, and is corrosion resistant. 5052 aluminum alloy is the highest strength alloy of the non-heat treatable grades. It has good resistance to marine atmosphere and salt water corrosion. With excellent workability it can be easily drawn and formed into intricate shapes.

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt