Wire And Cable Extrusion-7

| Item No.: | 5-7 |

Supplier Details

Country: Taiwan

City: New Taipei City 231

Address: No. 17, Ln. 42, Baoxing Rd., Xindian Dist.

TEL: +886-2-29181558

Fax: +886-2-29188158

Online Showroom:

40 Products

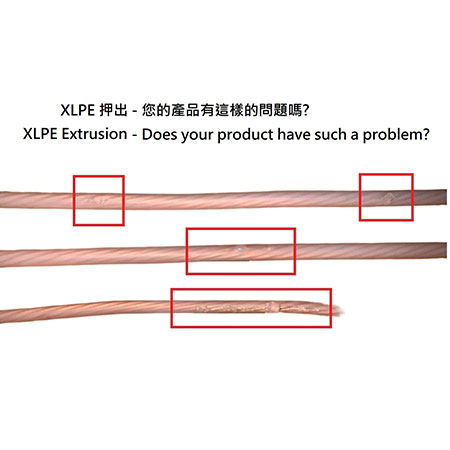

Wire and Cable Extrusion – XLPE Extrusion

XLPE plastics are mainly divided into one-dosage form and two-dosage form, the common two-dosage form, we can design very mature and stable at present. When extruding one-dosage form, it is prone to premature cross-linking or bad mixing. In order to deal with this problem, we have developed a special design to solve the most important surface particle problem of XLPE.

The excellent screw and barrel design can achieve the four major elements, including perfect mixing, no temperature rise, high production capacity, and good production stability.

In our experience:

65mm extruder motor configuration 40KW, the production capacity of extruding XLPE can reach about 145kg/H

90mm extruder motor configuration 75KW, the production capacity of extruding XLPE can reach about 270kg/H

Enlarging the motor can effectively increase the extrusion capacity.

The Screw and the Barrel are made of alloy steel imported from Japan, which has the advantages of wear resistance and long life.

To help our customers improve the extrusion speed, production capacity and mixing quality, and to create greater added value for customers' extrusion machines is our goal of continuous pursuit and improvement.

XLPE plastics are mainly divided into one-dosage form and two-dosage form, the common two-dosage form, we can design very mature and stable at present. When extruding one-dosage form, it is prone to premature cross-linking or bad mixing. In order to deal with this problem, we have developed a special design to solve the most important surface particle problem of XLPE.

The excellent screw and barrel design can achieve the four major elements, including perfect mixing, no temperature rise, high production capacity, and good production stability.

In our experience:

65mm extruder motor configuration 40KW, the production capacity of extruding XLPE can reach about 145kg/H

90mm extruder motor configuration 75KW, the production capacity of extruding XLPE can reach about 270kg/H

Enlarging the motor can effectively increase the extrusion capacity.

The Screw and the Barrel are made of alloy steel imported from Japan, which has the advantages of wear resistance and long life.

To help our customers improve the extrusion speed, production capacity and mixing quality, and to create greater added value for customers' extrusion machines is our goal of continuous pursuit and improvement.

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt