Washing Recycling Plants for Rigid Plastics

| Item No.: | 7-3. |

Supplier Details

Country: Taiwan

City: Taichung City 43444

Address: No.10-5, Tianzainei Ln., Sangang Rd., Longjing Dist.

TEL: +886-4-26301621

Fax: +886-4-26301716

Online Showroom:

20 Products

第7類3個描述重覆

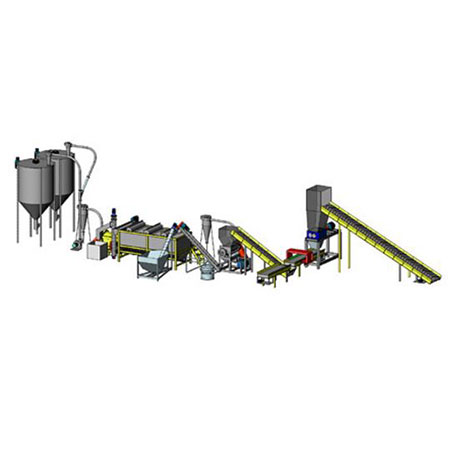

Washing/Recycling Plants for Rigid Plastics

Our PE/PP bottle/rigid washing plants are designed for recycling post-consumer bottles (like milk bottles) or rigid materials. These systems produce uniform size PE/PP flakes with high purity and low moisture level.

Washing/Recycling Plants for Rigid Plastics

Our PE/PP bottle/rigid washing plants are designed for recycling post-consumer bottles (like milk bottles) or rigid materials. These systems produce uniform size PE/PP flakes with high purity and low moisture level.

- Belt conveyor: to have a stable flow of quantity input, and minimize the labor cost, with metal detection optional.

- Wet-granulator: Wet type crusher can wash plastics preliminary to improve crushing efficiency and air-pollution by dust during crushing. Pre-shredders or hydraulic cutting machines are available for size reduction systems.

- Screw conveyor: to eliminate dusts, depending on the level of contamination.

- High speed friction washer: the device is equipped with water injection nozzles which spray the fresh water or recycled water directly at the screen cage to assist in screen cage cleaning and prevent clogging.

- Sink-float tank: Sink-Float Tanks separate different types of plastics by density, using sink-float principle. The heavier plastic fraction sink to the bottom of the tank whilst the lighter fractions float to the surface.

- Centrifugal dryer: After materials come out from the sink-float tank usually retains 80% or more of moisture. The centrifugal dryer helps reducing excess moisture, increasing the quality and efficiency of granulation.

- Jumbo bag station for storage.

- Control panel.

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt