Rod Seals -2

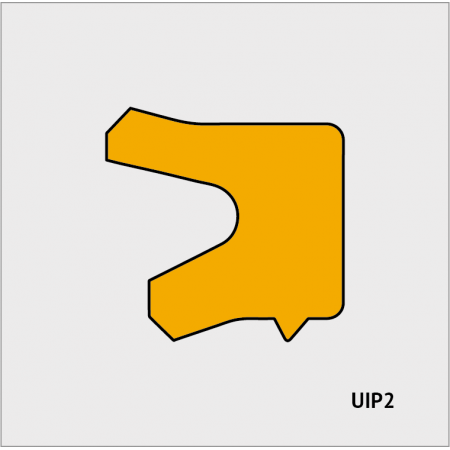

| Item No.: | UIP2 |

Supplier Details

Country: Taiwan

City: Nantou County

Address: No. 336, Gongye Rd., Nantou City

TEL: +886-49-2255011

Fax: +886-49-2250035

Online Showroom:

47 Products

Product Description

The UIP2 Rod Seal is a one-way, U-shaped rod seal with an asymmetrical design that not only has the shortened lip on its inner diameter similar to the UIP, but also comes with an additional sealing lip on its outer diameter. The second sealing lip provides additional protection, keeping dust and other contaminants from entering the front sealing lip. This helps to protect the mechanism, and prolongs the service life of the cylinder. The UIP2 Rod Seal is mostly used in construction and earth-moving machinery.

Material

Polyurethane

Product Advantages

Application

Earth-moving machinery, construction machinery, agricultural equipment, injection molding machines, fork-lifts, loading platforms and standard cylinders.

Operating Conditions

Gap Dimension

Surface Roughness

The UIP2 Rod Seal is a one-way, U-shaped rod seal with an asymmetrical design that not only has the shortened lip on its inner diameter similar to the UIP, but also comes with an additional sealing lip on its outer diameter. The second sealing lip provides additional protection, keeping dust and other contaminants from entering the front sealing lip. This helps to protect the mechanism, and prolongs the service life of the cylinder. The UIP2 Rod Seal is mostly used in construction and earth-moving machinery.

Material

Polyurethane

Product Advantages

- According to ISO 5597

- Good media resistance

- Excellent wear resistance

- Wide operating temperature range

- Very good static and dynamic tightness

- Secondary sealing lip provides additional protection against the ingress of dirt particles

Application

Earth-moving machinery, construction machinery, agricultural equipment, injection molding machines, fork-lifts, loading platforms and standard cylinders.

Operating Conditions

| Media | Mineral oils |

| Pressure | ≦40 Mpa |

| Speed | ≦0.5 m/s |

| Temperature Range | -40°C , +100°C |

Gap Dimension

| 140 Bar | 210 Bar | 350 Bar |

| 0.25 mm | 0.15 mm | 0.08 mm |

Surface Roughness

| Sliding Surface | Groove Base | Groove Flanks | |

| Ra | 0.2~0.4 µm | ≦0.8 µm | ≦3.2 µm |

| Rz | 0.8~1.6 µm | ≦3.2 µm | ≦12.5 µm |

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt