Traveling band screen

| Item No.: | TBS |

Supplier Details

Country: Taiwan

City: New Taipei City 242

Address: 8F.,No.354, Huacheng Rd.,Xinzhuang Dist

TEL: +886-2-22769961

Fax: +886-2-22769962

Online Showroom:

37 Products

The traveling band screen is fully automatic debris removal equipment. It can remove the debris both floating on water surface and submerged in water from inlet channel in order to prevent the followed mechanism from clogging and damage. The equipment is specially designed for debris removal purpose in the intake channel of power plant and desalination plant.

H+R had started the subject equipment supply from 1988 and completed the supply installation of subject equipment in seawater intake system more than 100 sets as yet with the auxiliary equipment included the stop gates and cable operated bar screens.

________________________________________

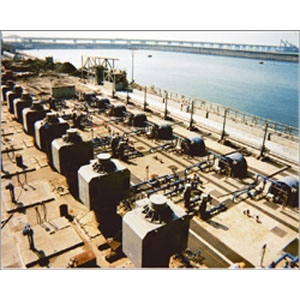

Cooling Water System Arrangement

a- Stop gate

b- Cable operated bar screen

c- Gate

d- Traveling band screen

e- Intake water Pump

Theory

The screening function of traveling band screen is provided by its endless semi-circular baskets, the baskets were fixed on two chain strips. The debris will be retained on baskets when the water passes through the screen. The water level differential will be increased along with the debris accumulation on baskets. As the water level differential reached the preset value, the driving system will be switched on automatically to rotate the baskets upward. The debris will be fallen down to debris trough by gravity and spray water will clean the baskets when basket reached the top of chain strip. The water level differential will be reduced when the clean baskets submerged into water again. The driving system will be switched off when the water level differential reduced to preset value and the screening cycle completed.

Basic Specification

a. The screening mesh can be varied from 0.1 to 10 mm.

b. The rotation speed can be constant, dual speed or tri-speed per requirement of operation condition.

c. Mechanical overload protection is provided.

d. Chain slack detector and alarm system were provided.

e. The intake channel width can be varied from 2.5 to 10 M.

Single or dual spray pipes can be selected per inlet S.S condition.

f. The designed water differential head can be varied from 0.5 to 3 M.

g. Chain pitch is 500 mm, water lubrication type.

Feature

1.Low construction cost

Under same submerged depth and chain length, the effective screening area of central flow type is 3 times of through flow type and 1.5 times of dual flow type.

Choose the central flow desigh can reduce the channel depth, pumping station dimension and save the construction cost.

2.Influent and clean water were isolated in two sides of screen meshes, no carry over concerns of debris.

3.No submerged sprockets, easy maintenance.

4.Water lubrication chain, maintenance free.

5.Unique suspension and shock absorption system of driving unit.

6.Seri-circular basket design

a.High debris retaining volume, increased screening efficiency.

b.High durability.

c.Easy dismantle and assembly, no special tool required.

7.Debris vertical gravity discharge.

a.Less pressure and flow rate of spray water, low initial and operation cost.

b.Can be operated without spray water, no debris carry over concern.

8.Spray water pipe located outside of screen mesh, easy operation and maintenance.

9.Accessible maintenance platform inside the equipment, easy maintenance.

10.Compact equipment arrangement, spacious maintenance space.

11.Can be interlocked with untrasonic level detector for reliable automatic operation.

12.Integral bypass valve ensure the equipment safety.

H+R had started the subject equipment supply from 1988 and completed the supply installation of subject equipment in seawater intake system more than 100 sets as yet with the auxiliary equipment included the stop gates and cable operated bar screens.

________________________________________

Cooling Water System Arrangement

a- Stop gate

b- Cable operated bar screen

c- Gate

d- Traveling band screen

e- Intake water Pump

Theory

The screening function of traveling band screen is provided by its endless semi-circular baskets, the baskets were fixed on two chain strips. The debris will be retained on baskets when the water passes through the screen. The water level differential will be increased along with the debris accumulation on baskets. As the water level differential reached the preset value, the driving system will be switched on automatically to rotate the baskets upward. The debris will be fallen down to debris trough by gravity and spray water will clean the baskets when basket reached the top of chain strip. The water level differential will be reduced when the clean baskets submerged into water again. The driving system will be switched off when the water level differential reduced to preset value and the screening cycle completed.

Basic Specification

a. The screening mesh can be varied from 0.1 to 10 mm.

b. The rotation speed can be constant, dual speed or tri-speed per requirement of operation condition.

c. Mechanical overload protection is provided.

d. Chain slack detector and alarm system were provided.

e. The intake channel width can be varied from 2.5 to 10 M.

Single or dual spray pipes can be selected per inlet S.S condition.

f. The designed water differential head can be varied from 0.5 to 3 M.

g. Chain pitch is 500 mm, water lubrication type.

Feature

1.Low construction cost

Under same submerged depth and chain length, the effective screening area of central flow type is 3 times of through flow type and 1.5 times of dual flow type.

Choose the central flow desigh can reduce the channel depth, pumping station dimension and save the construction cost.

2.Influent and clean water were isolated in two sides of screen meshes, no carry over concerns of debris.

3.No submerged sprockets, easy maintenance.

4.Water lubrication chain, maintenance free.

5.Unique suspension and shock absorption system of driving unit.

6.Seri-circular basket design

a.High debris retaining volume, increased screening efficiency.

b.High durability.

c.Easy dismantle and assembly, no special tool required.

7.Debris vertical gravity discharge.

a.Less pressure and flow rate of spray water, low initial and operation cost.

b.Can be operated without spray water, no debris carry over concern.

8.Spray water pipe located outside of screen mesh, easy operation and maintenance.

9.Accessible maintenance platform inside the equipment, easy maintenance.

10.Compact equipment arrangement, spacious maintenance space.

11.Can be interlocked with untrasonic level detector for reliable automatic operation.

12.Integral bypass valve ensure the equipment safety.

English

English

Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia