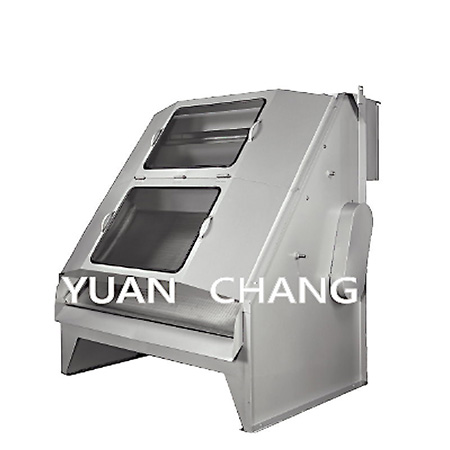

Liquid Solid Separation Equipment

| Item No.: | YU Series |

(Slanting Screen Type)

1. Structure and Principle

The sewage (waste) water feeds into filtration drum, the suspended particles which are greater than the diameter of the filter mesh will be attached to the wedge filter gaps of seam barrel. Through the filter drum slowly rotating ring spiral guide to clockwise, solids are brought to the outlet plate, but circulating water with solids smaller than the diameter of the filter mesh will go through the filter directly via the water pipe, back into the system for subsequent processing.

2. Purpose

- Hospital, livelihood sewage, city drainage intergrated treatment plant, printing / dyeing industry , textile industry, leather & tannery industry, paper-making industry, chemical industry, acquatic products processing factory, food industry, meat processing factory, butchery, industry, wine-making industry, sugar mill… etc. for removing the forepart dross and solid of the above wastewater treatment and solid / liquid separating engineering.

- For separating the floater from the animal husbandry sewage and solid / liquid separating treatment engineering.

- For the raw material recycling treatment of the paper & ulp industry.

- For protecting the post-equipment (pump) of the wastewater treatment to avoid to be clogged by the impurity.

3. Features

- The intercepted solids in the drum filter net stop turning, the use of Archimedes screw principle, to push and discharge the solids or impurities of the rotary drum continuously and intermittently for reaching the purpose of solid-liquid separation.

- With the High Pressure washing design from outside to inside self-cleaning drum filter net, it can effectively remove and clean the net or screen automatically to improve the filtering load capacity, and all solids or impurities fall back on the bottom of the net or screen when cleaning the net or screen, greatly enhance the recovery rate of solids or impurities.

- Wedge wire scren feature (for YU/DR/DG series):

① High structure strength, wear-resisting, durable, corrosion-resisting, long using life-span.

② With good filtration and enough filter opening to avoid to be clogged by the impurity.

③ With good treating result and expansive application for the field of the sieving, filtering, dewatering and solid / liquid separating.

Specification and Functions

The captured residues will be removed through the wedge wire screen to get the higher filtering result and lower clogging ratio.

Specification:

| Model & Spec. & Sieve slots | YU-70 | YU-130 | YU-190 | |||

| Treating capacity (Clean water) (m³/hr) | Sieve slots (Aperture) (mm) | 0.3 | 10.5 | 26 | 38 | |

| 0.5 | 36 | 87 | 129 | |||

| 1.0 | 44 | 108 | 161 | |||

| 1.5 | 48 | 117 | 174 | |||

| 2.0 | 54 | 132 | 197 | |||

| 3.0 | 81 | 198 | 295 | |||

| Power consumption (HP) | Standard | Low-pressure washing device driving motor | 1/2 | 1/2 | 1/2 | |

| High-pressure washing device driving motor | 40W | 40W × 2 | 40W × 3 | |||

| Optional | Low-pressure type washing pump (20~30kg/cm²) | Power consumption depends on the aperture demand | ||||

| High-pressure type washing pump (20~30kg/cm²) | Power consumption depends on the aperture demand | |||||

| Screw pump (Suitable for livestock , fiber slurry) | 2 | 2 | 3 | |||

| Machine frame material | Standard | Stainless Steel (SUS304) | ||||

| Optional | Stainless Steel (SUS316), (Other special materials) | |||||

| Reference machine dimensions (mm) | L | 1600 | 1600 | 1600 | ||

| W | 1050 | 1550 | 2150 | |||

| H | 1960 | 1960 | 1960 | |||

| W1 | 685 | 1285 | 1885 | |||

| H1 | 400 | 400 | 400 | |||

| Reference weight (kgs) | 390 | 490 | 600 | |||

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia