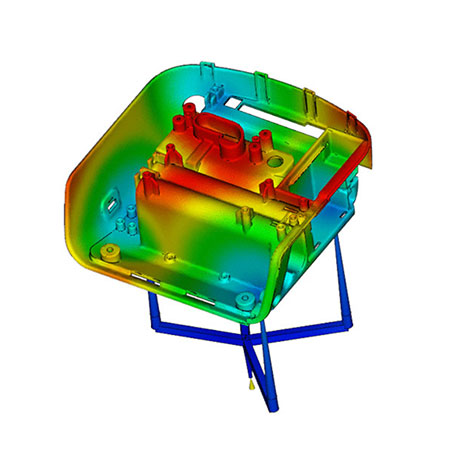

Mould Flow Analysis

| Item No.: | PMD-004 |

Supplier Details

Country: Taiwan

City: New Taipei City 236

Address: 3F., No. 6, Yongping St., Tucheng Dist.

TEL: +886-2-22697237

Fax: +886-2-22697615

Online Showroom:

40 Products

Particle Measuring Device Mold Flow Analysis

PMD-004

Three-plate mold with multi-gates and excellent conformal cooling channels.

Jawbone provides early stage small-volume production/trial production services:

Before formally mass production, we can make a small batch of trial production/pilot run for customers to verify the relevant quality requirements and process stability.

Plastic injection products be made in small quantity, and the minimum order for production is as following:

In response to the current demand in the market which always requires diverse products in a small quantity, Jawbone provides customers with a minimum order of 200 pcs per item. However, the small-quantity order will result in relatively higher production cost. Jawbone will provide customers the unit price of parts with different MOQ so they can make the most cost-effective choice for their purchasing order.

PMD-004

Three-plate mold with multi-gates and excellent conformal cooling channels.

- Development: Mold design and mold injection are according to customers’ CAD; offer free mold trial samples.

- Material: Makrolon 6557. All kinds of engineering plastic are available based on customers’ demands.

- Surface Finish: Texture. Both texture and polishing are available upon request.

- Color: Black. Colors can be customized upon request.

- Mold Base Steel: Select the most proper steel according to demands.

- Core Material: NAK-80 is the core material. Mold life can reach more than 300,000 shots.

- Demolding Mechanism: Provide solutions to expand life of mechanism actuation.

- Gate Type: Design the best runner system according to demands.

- Cooling System: Design the best conformal cooling channels according to structure of the product.

- Ejection System: Design the best ejection method according to structure of the product.

Jawbone provides early stage small-volume production/trial production services:

Before formally mass production, we can make a small batch of trial production/pilot run for customers to verify the relevant quality requirements and process stability.

Plastic injection products be made in small quantity, and the minimum order for production is as following:

In response to the current demand in the market which always requires diverse products in a small quantity, Jawbone provides customers with a minimum order of 200 pcs per item. However, the small-quantity order will result in relatively higher production cost. Jawbone will provide customers the unit price of parts with different MOQ so they can make the most cost-effective choice for their purchasing order.

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt