Plastic Mould Steel Material

| Item No.: |

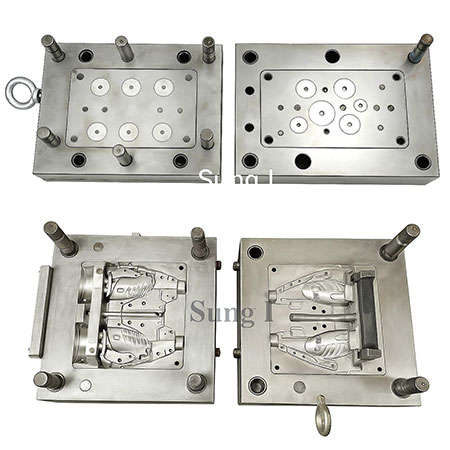

Injection Molding Design

Selecting the right mold steel type is essential for achieving optimal results in plastic injection molding. It influences not only product durability and precision, but also overall manufacturing cost and efficiency. Choosing the right steel at the mold development stage helps ensure a successful and scalable production process.

At Sung I Industrial, we offer complete technical consulting and custom manufacturing solutions—from design and steel selection to tooling and delivery—to support fully integrated vertical production. Whether you're working on large-scale OEM/ODM projects or high-performance transparent components, we can help you select the most suitable steel material for your needs.

More detailed note:

- P20 – Ideal for High-Speed Production of Small to Medium Parts

P20 is best for producing small to middle size products, especially where high-speed production is required. It offers an excellent balance of hardness and machinability. - P20+Ni – Optimal for Large Mold Applications with Smooth Finish

When working with large mold applications such as bumpers, dashboards, and TV cabinets, P20+Ni is an excellent choice. It delivers a smooth and shiny surface, meeting the aesthetic demands of larger consumer products. - NAK80 – Premium Choice for Transparent Plastic Components

NAK80 is specially designed for transparent plastic components including camera lenses, tail light covers, and LED lenses. It offers high polish ability, resulting in high brightness and strength—perfect for parts requiring both clarity and durability.

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt