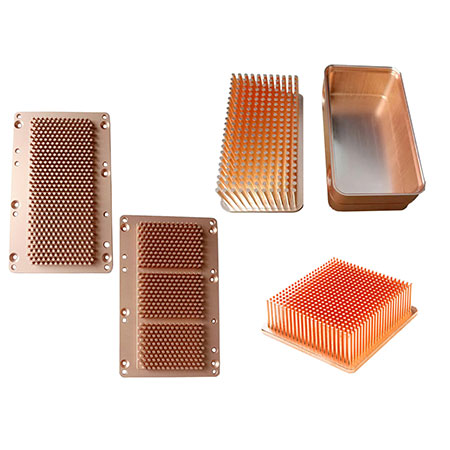

Copper Heat Sink

| Item No.: | 5-1 |

Supplier Details

Country: Taiwan

City: New Taipei City 238

Address: No. 8, Ln. 292, Sanjun St., Shulin Dist.

TEL: +886-2-29013089

Fax: +886-2-26761337

Online Showroom:

53 Products

Copper Forged Heat Sink

Today's forging process has been applied to heat sink products that require efficient heat dissipation.

Cold forged heat sinks can be used to make high-density heat dissipation pin posts or heat dissipation fins.

The heat dissipation pin post has a larger heat conduction area and heat dissipation space than the heat dissipation fins.

Under the conditions of the same material and the same size, the cold forged heat sink can improve the heat dissipation efficiency by 13~20% compared with the extrusion heat sink, and improve the heat dissipation efficiency by 5~10% compared with the skiving type heat sink.

Cold forging process is carried out at normal atmospheric temperature for forging products, high dimensional and shape accuracy, high internal density and strength, smooth surface, less machining processes and permits the mass production.

We are certificated by the ISO 9001:2015 qualification. If you interest in our products or require any further information, feel free to contact us please.

- Material: C11000 Copper.

- Size: Varieties, OEM Custom

- Manufacture Category: Copper Cold Forging, CNC Machining, Stamping, Anti-Oxidize

- Application: Computer Cooling products, 3C Products, Industrial Products, Lighting

- Origin, Place of shipment: Taiwan or China TBD

- Package: Standard package

- Shipment: sea freight, air freight, express delivery

- EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

Today's forging process has been applied to heat sink products that require efficient heat dissipation.

Cold forged heat sinks can be used to make high-density heat dissipation pin posts or heat dissipation fins.

The heat dissipation pin post has a larger heat conduction area and heat dissipation space than the heat dissipation fins.

Under the conditions of the same material and the same size, the cold forged heat sink can improve the heat dissipation efficiency by 13~20% compared with the extrusion heat sink, and improve the heat dissipation efficiency by 5~10% compared with the skiving type heat sink.

Cold forging process is carried out at normal atmospheric temperature for forging products, high dimensional and shape accuracy, high internal density and strength, smooth surface, less machining processes and permits the mass production.

We are certificated by the ISO 9001:2015 qualification. If you interest in our products or require any further information, feel free to contact us please.

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt