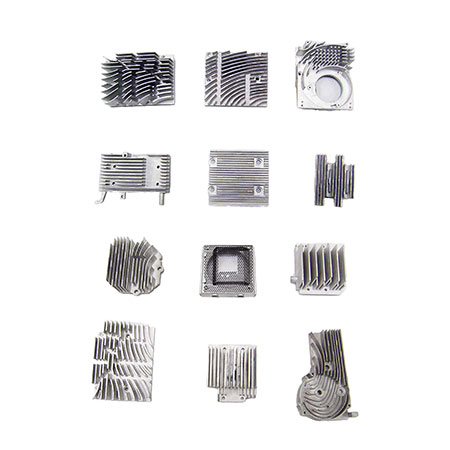

Heat Dissipation Unit

| Item No.: | 3-5 |

Supplier Details

Country: Taiwan

City: New Taipei City 238

Address: No. 8, Ln. 292, Sanjun St., Shulin Dist.

TEL: +886-2-29013089

Fax: +886-2-26761337

Online Showroom:

53 Products

Die Casting - Heat Dissipation Unit

We have produced many customized aluminum heat sink die-casting parts, which are widely used in computer information industry, communication industry, and 3C electronic products.

Die cast aluminum heat sinks are cheaper than extrusion if the quantity required is large.

Aluminum heat sinks with complex shapes can be produced by die casting to reduce costs.

We have the ability to provide our 30 years of experience in metal fabrication and processing to advise customers on the most cost-effective processing and manufacturing methods.

Any of our products you are interested in, please contact us.

- Material:Aluminum Die Casting (ADC10/A380, ADC12/A383)

- Size: Varieties, OEM Custom

- Processing, category: die casting (aluminum, zinc), CNC machining, drilling, glass bead blasting, sand blasting, brushing, polishing, painting, powder coating, silk screen printing, assembly.

- Coating/Surface Treatment: Anodizing (Color/Clear), Hard Anodizing, Powder Coating, Electroplating, Chrome Plating, Nickel Plating, Painting, Electro‑deposition painting (ED Coating), laser engraving.

- Applications: Various mechanical parts; electrical parts; mechanical hardware parts; pneumatic tool parts; automobile parts; sports equipment and, etc.

- Package: Standard package

- Shipment: sea freight, air freight, express delivery

- EU RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) compliant products.

We have produced many customized aluminum heat sink die-casting parts, which are widely used in computer information industry, communication industry, and 3C electronic products.

Die cast aluminum heat sinks are cheaper than extrusion if the quantity required is large.

Aluminum heat sinks with complex shapes can be produced by die casting to reduce costs.

We have the ability to provide our 30 years of experience in metal fabrication and processing to advise customers on the most cost-effective processing and manufacturing methods.

Any of our products you are interested in, please contact us.

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt