Piston Seals -4

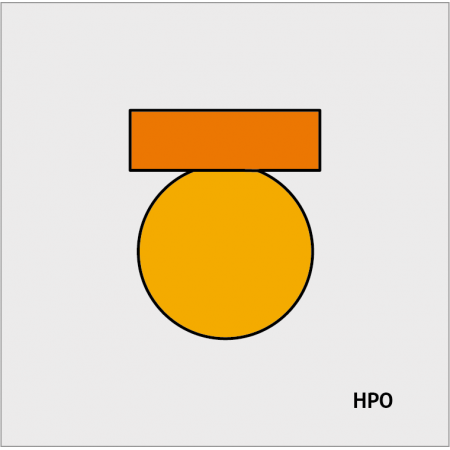

| Item No.: | HPO |

Supplier Details

Country: Taiwan

City: Nantou County

Address: No. 336, Gongye Rd., Nantou City

TEL: +886-49-2255011

Fax: +886-49-2250035

Online Showroom:

47 Products

Product Description

The HPO Piston Seals are a combination seal made of a PTFE profile ring and an O-Ring energizer. The PTFE seal has low friction characteristics which make it perfect for reducing energy loss and increasing the service life of the mechanism. Since the PTFE profile ring has a wide operating temperature range, the seal’s operating temperature range can be suitably adjusted by choosing an optimum O-Ring material. Thus providing a wide temperature range for the Seal. While similar to an HOD Piston Seal, the HPO Piston Seal can save installation space, while still being able to maintain a tight seal for a high-speed, high pressure, double acting environment.

Material

O-Ring -NBR

Friction Ring -PTFE

Product Advantages

Application

Agricultural equipment, injection molding machines, fork-lifts and loading platforms

Operating Conditions

Gap Dimension

Surface Roughness

The HPO Piston Seals are a combination seal made of a PTFE profile ring and an O-Ring energizer. The PTFE seal has low friction characteristics which make it perfect for reducing energy loss and increasing the service life of the mechanism. Since the PTFE profile ring has a wide operating temperature range, the seal’s operating temperature range can be suitably adjusted by choosing an optimum O-Ring material. Thus providing a wide temperature range for the Seal. While similar to an HOD Piston Seal, the HPO Piston Seal can save installation space, while still being able to maintain a tight seal for a high-speed, high pressure, double acting environment.

Material

O-Ring -NBR

Friction Ring -PTFE

Product Advantages

- Good media resistance

- Low frictional resistance

- Wide operating temperature range depending on the O-Ring material

- Very good static and dynamic tightness

- High-speed sliding

- Fit small grooves heights

Application

Agricultural equipment, injection molding machines, fork-lifts and loading platforms

Operating Conditions

| Media | Mineral oils |

| Pressure | ≦35 Mpa |

| Speed | ≦1.5 m/s |

| Temperature Range | -40°C , +100°C |

Gap Dimension

| 200 Bar | 250 Bar | 350 Bar |

| 0.6 mm | 0.42 mm | 0.25 mm |

Surface Roughness

| Sliding Surface | Groove Base | Groove Flanks | |

| Ra | 0.1~0.8 µm | ≦1.6 µm | ≦3.2 µm |

| Rz | 0.4~3.2 µm | ≦6.3 µm | ≦12.5 µm |

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt