Piston Seals -3

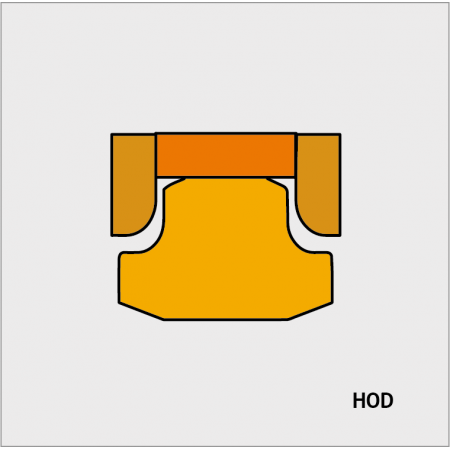

| Item No.: | HOD |

Supplier Details

Country: Taiwan

City: Nantou County

Address: No. 336, Gongye Rd., Nantou City

TEL: +886-49-2255011

Fax: +886-49-2250035

Online Showroom:

47 Products

Product Description

The HOD Piston Seal is a four-piece combination seal used in heavy-duty hydraulic cylinders. The primary PTFE seal is made of low-friction materials which is perfect for the high-speed and high pressure hydraulic cylinder application. The HOD Piston Seal is a double acting seal and is supported by nylon back-up rings on either side to allow sealing and protect the main PTFE profile from high pressures on both sides of the piston. Together, this combination seal can withstand pressures of up to 50Mpa. The HOD Piston Seal is mostly used in mining equipment, construction machinery and high-speed hydraulic cylinders.

Material

NBR

Nylon

Friction Ring -PTFE

Product Advantages

Application

Mining equipment, Earth-moving machinery and construction machinery

Operating Conditions

Gap Dimension

Surface Roughness

The HOD Piston Seal is a four-piece combination seal used in heavy-duty hydraulic cylinders. The primary PTFE seal is made of low-friction materials which is perfect for the high-speed and high pressure hydraulic cylinder application. The HOD Piston Seal is a double acting seal and is supported by nylon back-up rings on either side to allow sealing and protect the main PTFE profile from high pressures on both sides of the piston. Together, this combination seal can withstand pressures of up to 50Mpa. The HOD Piston Seal is mostly used in mining equipment, construction machinery and high-speed hydraulic cylinders.

Material

NBR

Nylon

Friction Ring -PTFE

Product Advantages

- Excellent media resistance in case of suitable compound selection

- Excellent gap extrusion resistance

- Very good dynamic tightness even with pressure peaks

- High-speed sliding

Application

Mining equipment, Earth-moving machinery and construction machinery

Operating Conditions

| Media | Mineral oils |

| Pressure | ≦50 Mpa |

| Speed | ≦1.5 m/s |

| Temperature Range | -40°C , +100°C |

Gap Dimension

| 510 Bar | 650 Bar | 800 Bar |

| 1 mm | 0.45 mm | 0.19 mm |

Surface Roughness

| Sliding Surface | Groove Base | Groove Flanks | |

| Ra | 0.1~0.8 µm | ≦1.6 µm | ≦3.2 µm |

| Rz | 0.4~3.2 µm | ≦6.3 µm | ≦12.5 µm |

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt