Flame Spray Technologies

| Item No.: | B4 |

Supplier Details

Country: Taiwan

City: Taiwan(ROC)

Address: No.59, Dade Rd. Xinhua Dist., Tainan City 712

TEL: +886-6-5983553

Fax: +886-6-5980753

Online Showroom:

44 Products

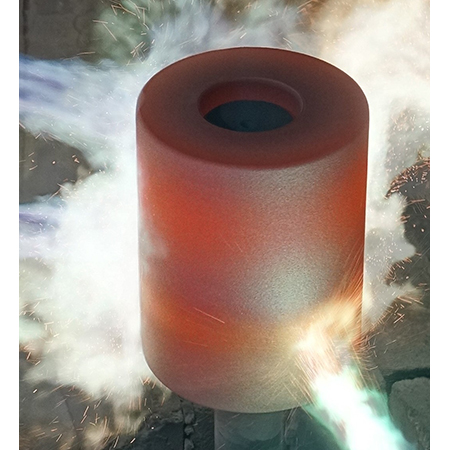

<Flame Spray and Fusion>

Thermal sprayed self-fluxing alloys can be applied on a substrate by any available spray process including flame spray and plasma spray. The fused coatings are dense and metallurgically bonded to the substrate. The fused coating can impart wear resistance, corrosion resistance, oxidation resistance in a temperature ranging from room temperature to high temperature. The alloy materials are used to repair or build up worn, damaged, or improperly machined parts as well as to provide protection to new parts.

Wear resistance can be improved by alloying carbides with thermal spray powders. The hard carbide parts in combination with a ductile matrix alloy will provide extreme hardness and extreme wear resistance. Thermal spray powders that contain wolfram carbides(or tungsten carbide) is favorable for medium temperatures applications below 500˚C. Wolfram carbide coatings are characterized by their extreme wear resistance. Furthermore, corrosion resistance will be improved enormously by adding chrome metal. That makes tungsten carbide coatings extremely suitable for the applications of steel, paper & pulp, oil, gas and petrochemical industry.

At higher process temperatures (up to 850˚C), coatings based on chrome carbide perform better resistant to high-temperature corrosion. For the client's specific application requirements, bond material ranging from 10 to 50 percent will carry out the combination of hardness and ductility.

Plus Metal Tech (PMT) provides services of protective and functional coatings, such as wear-resistant, corrosion-resistant, erosion-resistant, conductive and insulative coatings. Our thermal coating service is fully customized. Process choices depend on customer’s demands and the chosen materials. For any questions about surface treatment and enhancement, please do not hesitate to give us the message or email. We welcome for the discussion with you.

Thermal sprayed self-fluxing alloys can be applied on a substrate by any available spray process including flame spray and plasma spray. The fused coatings are dense and metallurgically bonded to the substrate. The fused coating can impart wear resistance, corrosion resistance, oxidation resistance in a temperature ranging from room temperature to high temperature. The alloy materials are used to repair or build up worn, damaged, or improperly machined parts as well as to provide protection to new parts.

Wear resistance can be improved by alloying carbides with thermal spray powders. The hard carbide parts in combination with a ductile matrix alloy will provide extreme hardness and extreme wear resistance. Thermal spray powders that contain wolfram carbides(or tungsten carbide) is favorable for medium temperatures applications below 500˚C. Wolfram carbide coatings are characterized by their extreme wear resistance. Furthermore, corrosion resistance will be improved enormously by adding chrome metal. That makes tungsten carbide coatings extremely suitable for the applications of steel, paper & pulp, oil, gas and petrochemical industry.

At higher process temperatures (up to 850˚C), coatings based on chrome carbide perform better resistant to high-temperature corrosion. For the client's specific application requirements, bond material ranging from 10 to 50 percent will carry out the combination of hardness and ductility.

Plus Metal Tech (PMT) provides services of protective and functional coatings, such as wear-resistant, corrosion-resistant, erosion-resistant, conductive and insulative coatings. Our thermal coating service is fully customized. Process choices depend on customer’s demands and the chosen materials. For any questions about surface treatment and enhancement, please do not hesitate to give us the message or email. We welcome for the discussion with you.

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia