Extrusion Solution-4

| Item No.: | 7-4 |

Supplier Details

Country: Taiwan

City: New Taipei City 231

Address: No. 17, Ln. 42, Baoxing Rd., Xindian Dist.

TEL: +886-2-29181558

Fax: +886-2-29188158

Online Showroom:

40 Products

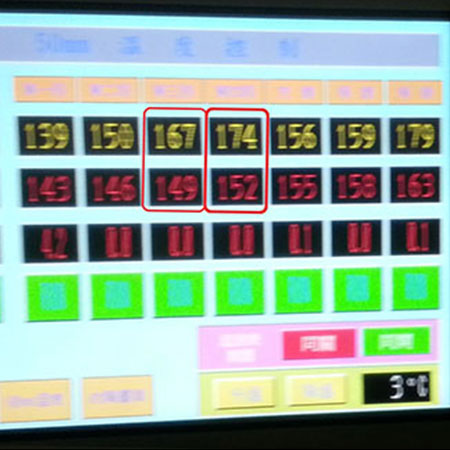

The temperature rises at Metering zone of the extrusion production

The problem of temperature rise in extrusion production has always been a common problem for designers of extruder screw and barrel.

The temperature rise block is roughly divided into three sections: feeding section, compression section, and metering section, based on the design of the screw.

The temperature rise in the metering section can be roughly divided into several points

When we face the temperature rise in the metering section, we should first determine which link is generated, and then make the next review and adjustment.

The problem of temperature rise in extrusion production has always been a common problem for designers of extruder screw and barrel.

The temperature rise block is roughly divided into three sections: feeding section, compression section, and metering section, based on the design of the screw.

The temperature rise in the metering section can be roughly divided into several points

- 1: The temperature rise of the metering section is the back pressure generated by the barrel outlet connecting to the die mouth. When the extrusion speed and output increase, the pressure entering the die mouth will increase. When the barrel outlet pressure increases, the temperature rises obviously. When the screw speed is reduced, the relative temperature rise will also ease. In addition to reducing the operating speed, increasing the set temperature is also an approach way can be tried.

- 2: The wear of the screw will also cause the temperature of the metering section to rise, because the pressure of the screw to push the plastic is not enough, so that the plastic stays in the metering section for too long, so that the temperature of the plastic rises.

- 3: The temperature setting is too low when extruding plastics with poor fluidity. In this case, it is more likely to increase the back pressure due to poor fluidity, resulting in a rise in temperature, especially if plastics with carbon or metal added. Plastic. Such as: conductive plastic, or LSHF plastic.

When we face the temperature rise in the metering section, we should first determine which link is generated, and then make the next review and adjustment.

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt