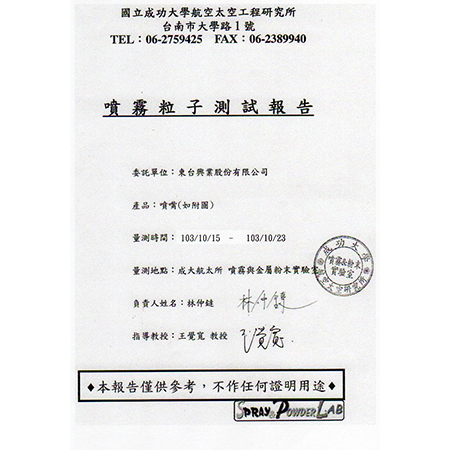

Experimental Measurement of nozzle particle size 1

| Item No.: | 3-1 |

Supplier Details

Country: Taiwan

City: Taichung

Address: 30-2, 31Th RD. Taichung Ind. Dist.

TEL: +886-4-23588168

Fax: +886-4-23588598

Online Showroom:

48 Products

Fog machines spray particle size measurement

I. Experiments measuring device

i. Spray Performance Test Bench

a. Spray measuring bench

FIG 1 is the front view and measure view of the spray measuring bench, the relative size as showned.

Laser measurement device is fixed thereto spray measuring carriage. The nozzle to be test suspended

on a three-dimensional moving platform. When we want to adjust the measurement position, we can

just move the nozzle position by stepping motor, to adjust the relative position between the nozzle

and the laser.

b. Stepping Motor

Three-dimensional moving platform controlled by a microcomputer stepper motor to adjust the nozzle

position in x, y, z three directions to do the spray measurement work.

ii. Liquid supply system

a. RO filter

In this experiments, we use the pure water been filtered by the RO filter, to avoid the impurities of the

water to contaminate the nozzle system, affecting the nozzle test results.

b. Liquid pressure system

The pressurized fluid is measured to be provided the desired source pressure by the high pressure gas.

First, we filled the measured liquid into the pressure accumulator, then injected into the high-pressure

gas therein, and to maintain a stable pressure in the testing process, in order to improve the quality of

the nozzle test. High-pressure gas can be compressed by gas cylinders or compressor.

c. Rotameter

In two kinds of liquid flow meter to measure, included Dwyer Rotameter,

measurement range is 0~1.0 GPM(gallon/min)

AALBORG Rotameter,

measurement range is 0~500 ml/min。

iii. The desired nozzle pressure gas supply system

a. Compressor

Continuous high-pressure gas atomization of the desired tip provided by a large compressor pressure

up to 8kg / cm2.

b. Gas mass flow meter

We use AALBORG Company Model GFM471 atomizing gas flow measured the gas mass flow,

measuring ranges is 0 ~ 100LPM (l / min) and 0 ~ 200 LPM (l / min).

iv. Pumping system

Pumping systems are under inverter control the amount of exhaust blower, discharge the spray mist

particles to outdoors, avoid its retention test area, causing the measurement error.

v. Particle size measurement analyzer

Measuring particle size analysis of the test data used in the device is Model No.SDP-ESPES2.0E-195,

RT-Sizer particle size analyzer of Malvern UK, the acquisition in August 2000, its measurement principle

and measurement method as follows:

I. Experiments measuring device

i. Spray Performance Test Bench

a. Spray measuring bench

FIG 1 is the front view and measure view of the spray measuring bench, the relative size as showned.

Laser measurement device is fixed thereto spray measuring carriage. The nozzle to be test suspended

on a three-dimensional moving platform. When we want to adjust the measurement position, we can

just move the nozzle position by stepping motor, to adjust the relative position between the nozzle

and the laser.

b. Stepping Motor

Three-dimensional moving platform controlled by a microcomputer stepper motor to adjust the nozzle

position in x, y, z three directions to do the spray measurement work.

ii. Liquid supply system

a. RO filter

In this experiments, we use the pure water been filtered by the RO filter, to avoid the impurities of the

water to contaminate the nozzle system, affecting the nozzle test results.

b. Liquid pressure system

The pressurized fluid is measured to be provided the desired source pressure by the high pressure gas.

First, we filled the measured liquid into the pressure accumulator, then injected into the high-pressure

gas therein, and to maintain a stable pressure in the testing process, in order to improve the quality of

the nozzle test. High-pressure gas can be compressed by gas cylinders or compressor.

c. Rotameter

In two kinds of liquid flow meter to measure, included Dwyer Rotameter,

measurement range is 0~1.0 GPM(gallon/min)

AALBORG Rotameter,

measurement range is 0~500 ml/min。

iii. The desired nozzle pressure gas supply system

a. Compressor

Continuous high-pressure gas atomization of the desired tip provided by a large compressor pressure

up to 8kg / cm2.

b. Gas mass flow meter

We use AALBORG Company Model GFM471 atomizing gas flow measured the gas mass flow,

measuring ranges is 0 ~ 100LPM (l / min) and 0 ~ 200 LPM (l / min).

iv. Pumping system

Pumping systems are under inverter control the amount of exhaust blower, discharge the spray mist

particles to outdoors, avoid its retention test area, causing the measurement error.

v. Particle size measurement analyzer

Measuring particle size analysis of the test data used in the device is Model No.SDP-ESPES2.0E-195,

RT-Sizer particle size analyzer of Malvern UK, the acquisition in August 2000, its measurement principle

and measurement method as follows:

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt