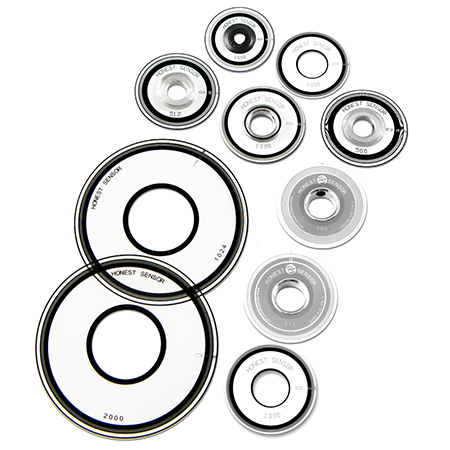

ENCODER DISC

| Item No.: | PLASTIC DISC |

Supplier Details

Country: Taiwan

City: Taiwan

Address: 3F., No. 33-5, Shoushan Rd., Xinzhuang Dist., New Taipei City 242, Taiwan(R.O.C)

TEL: +886-2-29086896

Fax: +886-2-29083598

Online Showroom:

1 Products

* History of product development

The traditional film discs are made of photographic films. There are two production steps. First, discs will be drawn as disc pattern by laser plotter. Second, they will be molded by stamping or by laser cutting.

The typical photographic film is 0.18mm. The operating temperature that it is well suited to subzero twenty to eighty degrees centigrade can meet the demands of industrial environment temperature. With industrial automation maturity and rising popularizing rate, customers hope that the nature of film can be similar to glass, and have more demands for file materials.

* Basic specifications ( size / weight / color / power / origin ... etc. )

The Honest Sensor Corporation is still devoted to develop new materials in the applications of encoder disc. We not only redefine plastic encoder disc, but also provide more diversified solutions. For example, we have offered the polycarbonate encoder discs. There are more sizes, such as 0.18 mm, 0.25 mm, 0.5 mm, 0.7 mm, and 1.0 mm etc. Besides sizes, the

wide operating temperature range, subzero forty to one hundred twenty degrees centigrade, is one of features of resin disc.

The application ranges of encoder are very widely, such as the following information.

Label printer

Plotter

Medical diagnosis machine

Conveyor

Mechanical arm

Elevator door

Elevator

Textile machine

Storage equipment

Articles inspection machine

Fixed-length cutting machine

Servo encoder

Automatic filling machine

CNC machine center

* Features stressing and comparing

Material properties:

It has more features, as colorless, heat tolerance, impact resistance,

flame retardation, good mechanical performance. Its properties also are similar to glass.

Thickness:

There are multiple specifications, such as 0.18 mm, 0.25 mm, 0.5 mm, 0.7 mm, 1.0 mm, 1.5 mm, and 2.0 mm etc. These can be instead of the thickness of glass.

Operation temperature:

The polycarbonate, which can adapt temperature from subzero forty to one hundred twenty degrees centigrade, is better than photographic film, because it can meet the demands of most industrial environments.

Flatness:

The flatness of polycarbonate is superior to photographic film due to its features.

Reliability:

Due to the properties of polycarbonate, it is not easy to injury and broken.

Low cost:

After comparing glass material, the costs of polycarbonate are more competitive.

The Honest Sensor Corporation can provide specific inspection reports that customer need, and use professional inspection equipments to inspect the ninety nine track widths in short time.

* Production methods (Processing)

The polycarbonate is coated with metal, and the pattern of disc will be transfer printing on metal by etching process. Finally, it will be cutting the specific sizes, which customers need, by professional molding technology.

The traditional film discs are made of photographic films. There are two production steps. First, discs will be drawn as disc pattern by laser plotter. Second, they will be molded by stamping or by laser cutting.

The typical photographic film is 0.18mm. The operating temperature that it is well suited to subzero twenty to eighty degrees centigrade can meet the demands of industrial environment temperature. With industrial automation maturity and rising popularizing rate, customers hope that the nature of film can be similar to glass, and have more demands for file materials.

* Basic specifications ( size / weight / color / power / origin ... etc. )

The Honest Sensor Corporation is still devoted to develop new materials in the applications of encoder disc. We not only redefine plastic encoder disc, but also provide more diversified solutions. For example, we have offered the polycarbonate encoder discs. There are more sizes, such as 0.18 mm, 0.25 mm, 0.5 mm, 0.7 mm, and 1.0 mm etc. Besides sizes, the

wide operating temperature range, subzero forty to one hundred twenty degrees centigrade, is one of features of resin disc.

The application ranges of encoder are very widely, such as the following information.

Label printer

Plotter

Medical diagnosis machine

Conveyor

Mechanical arm

Elevator door

Elevator

Textile machine

Storage equipment

Articles inspection machine

Fixed-length cutting machine

Servo encoder

Automatic filling machine

CNC machine center

* Features stressing and comparing

Material properties:

It has more features, as colorless, heat tolerance, impact resistance,

flame retardation, good mechanical performance. Its properties also are similar to glass.

Thickness:

There are multiple specifications, such as 0.18 mm, 0.25 mm, 0.5 mm, 0.7 mm, 1.0 mm, 1.5 mm, and 2.0 mm etc. These can be instead of the thickness of glass.

Operation temperature:

The polycarbonate, which can adapt temperature from subzero forty to one hundred twenty degrees centigrade, is better than photographic film, because it can meet the demands of most industrial environments.

Flatness:

The flatness of polycarbonate is superior to photographic film due to its features.

Reliability:

Due to the properties of polycarbonate, it is not easy to injury and broken.

Low cost:

After comparing glass material, the costs of polycarbonate are more competitive.

The Honest Sensor Corporation can provide specific inspection reports that customer need, and use professional inspection equipments to inspect the ninety nine track widths in short time.

* Production methods (Processing)

The polycarbonate is coated with metal, and the pattern of disc will be transfer printing on metal by etching process. Finally, it will be cutting the specific sizes, which customers need, by professional molding technology.

English

English

Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia