Sludge Dryer

| Item No.: | VD Series |

Supplier Details

Country: Taiwan

City: TAIWAN(R.O.C)

Address: NO.106,LN.382,SEC.9,XIANGSHANG RD.,Wu-Chi DIST.,TAICHUNG CITY

TEL: +886-4-26305899

Fax: +886-4-26308299

Online Showroom:

41 Products

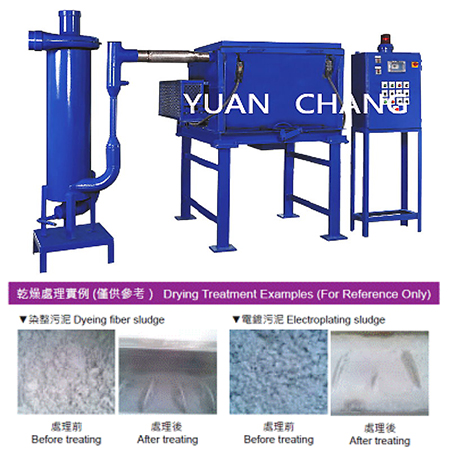

Drying Treatment System (Electric drying equipment)

1. Structure and Principle

Dryer heat source is electric heating strip, equipped in the dryer barrel outer body. Dryer shell has insulation layer, a rotatable stirrer is installed in the dryer body. Electric heating strips are used to generate high temperature heat to dry sludge by heat conduction. The system design uses closed fit operation, dust filtration system to accelerate the drying process by sucking out wet air and filtering dust.

2. Purpose

3. Features

Chemical sludge and bio-solids best drying reduction system, simple operation and good effect, fast drying process. Dryer has "sealed package" seal on the propeller stirrer bearing to prevent sludge and moisture from entering the bearing.

4. Specification and Functions

All internal parts are made of stainless steel, with a propeller stirrer blade moves back and forth inside and outside the sludge. The system employs a batch operation, the drying capacity is designed according to customer demand, control system automatically operating the drying process.

Specification:

1. Structure and Principle

Dryer heat source is electric heating strip, equipped in the dryer barrel outer body. Dryer shell has insulation layer, a rotatable stirrer is installed in the dryer body. Electric heating strips are used to generate high temperature heat to dry sludge by heat conduction. The system design uses closed fit operation, dust filtration system to accelerate the drying process by sucking out wet air and filtering dust.

2. Purpose

- High-performance drying equipment, the high moisture content of wet sludge, dried reduction to low moisture content of sludge.

- Organic sludge and inorganic sludge best drying reduction equipment.

- Suitable for paste, pasty and powder materials drying and reducing.

- Application of the low moisture content of the sludge drying quickly.

3. Features

Chemical sludge and bio-solids best drying reduction system, simple operation and good effect, fast drying process. Dryer has "sealed package" seal on the propeller stirrer bearing to prevent sludge and moisture from entering the bearing.

4. Specification and Functions

All internal parts are made of stainless steel, with a propeller stirrer blade moves back and forth inside and outside the sludge. The system employs a batch operation, the drying capacity is designed according to customer demand, control system automatically operating the drying process.

Specification:

| Model Spec. | VD1-120 | VD1-250 | VD2-500 | VD2-900 | VD2-1500 | VD2-2200 | VD2-3000 |

| Treating capacity (L/batch) | 120 | 250 | 500 | 900 | 1500 | 2200 | 3000 |

| Auger type | Single-Auger | Double-Auger | |||||

| Dried time (hr/batch) | 3~9 | ||||||

| Moisture content rate after drying (%) (Depends on sludge feature & dried time) | 10~40 (organic / inorganic) | ||||||

| Machine frame material | Carbon Steel + Stainless Steel | ||||||

| Heating method | Electric Heater / Steam | ||||||

| Drying temperature (℃) | 100 ~ 140 | ||||||

| Wet scrubber(Optional) | Few amount of dust removing function | ||||||

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia