Chromium Oxide Coating

| Item No.: | E3 |

Supplier Details

Country: Taiwan

City: Taiwan(ROC)

Address: No.59, Dade Rd. Xinhua Dist., Tainan City 712

TEL: +886-6-5983553

Fax: +886-6-5980753

Online Showroom:

44 Products

<Chromium Oxide Coating>

Excellent chromium oxide coatings are achieved using the atmospheric plasma process.

Addition of titanium oxide improves the cohesive strength and will have higher fracture toughness. Compared to zirconia-based ceramic coatings, chromium oxide coatings have higher microhardness and macrohardness; however, they exhibit higher thermal conductivity and are not so thermally insulative.

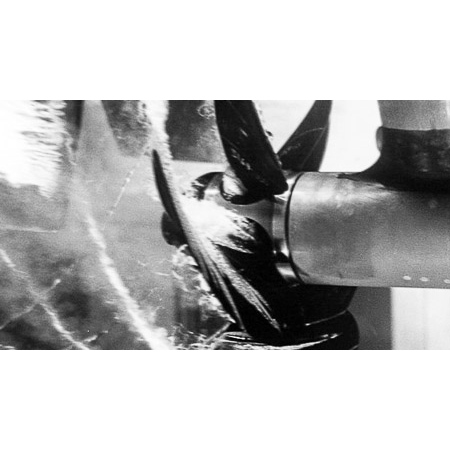

Chrome oxide coatings are useful in a wide range of applications. They are highly effective for sealing applications to improve abrasion and wear resistance and protect components from contamination. Chrome oxide coatings are commonly applied to pump components, rotating equipment and other applications about resistance to wear and chemical attack.

Applications of chromium oxide coatings include laser engraved anilox rollers, roller for paper and pulp industry, pump seals, shafts and wear rings, chemical industry components, textile industry components and biomedical implants.

Our chromium oxide coating is dense, hard and resistant to wear. This material is recommended for resistance to wear by abrasive grains, hard surfaces, particle erosion and cavitation below 540 ̊C (1,000 ̊F). These coatings are chemically stable in acids, alkalis and alcohol. When properly sealed, they are recommended for use in corrosive chemical environments in temperatures up to 200 ̊C (392 ̊F). Additionally, chromium oxide coating can also be applied for some applications that require relatively coarse, brush finished, hard, wear and corrosion resistant surface such as machine element which comes into contact with fibers and threads in textile industry.

Plus Metal Tech (PMT) provides services of protective and functional coatings, such as wear-resistant, corrosion-resistant, erosion-resistant, conductive and insulative coatings. Our thermal coating service is fully customized. Process choices depend on customer’s demands and the chosen materials. For any questions about surface treatment and enhancement, please do not hesitate to give us the message or email. We welcome for the discussion with you.

Excellent chromium oxide coatings are achieved using the atmospheric plasma process.

Addition of titanium oxide improves the cohesive strength and will have higher fracture toughness. Compared to zirconia-based ceramic coatings, chromium oxide coatings have higher microhardness and macrohardness; however, they exhibit higher thermal conductivity and are not so thermally insulative.

Chrome oxide coatings are useful in a wide range of applications. They are highly effective for sealing applications to improve abrasion and wear resistance and protect components from contamination. Chrome oxide coatings are commonly applied to pump components, rotating equipment and other applications about resistance to wear and chemical attack.

Applications of chromium oxide coatings include laser engraved anilox rollers, roller for paper and pulp industry, pump seals, shafts and wear rings, chemical industry components, textile industry components and biomedical implants.

Our chromium oxide coating is dense, hard and resistant to wear. This material is recommended for resistance to wear by abrasive grains, hard surfaces, particle erosion and cavitation below 540 ̊C (1,000 ̊F). These coatings are chemically stable in acids, alkalis and alcohol. When properly sealed, they are recommended for use in corrosive chemical environments in temperatures up to 200 ̊C (392 ̊F). Additionally, chromium oxide coating can also be applied for some applications that require relatively coarse, brush finished, hard, wear and corrosion resistant surface such as machine element which comes into contact with fibers and threads in textile industry.

Plus Metal Tech (PMT) provides services of protective and functional coatings, such as wear-resistant, corrosion-resistant, erosion-resistant, conductive and insulative coatings. Our thermal coating service is fully customized. Process choices depend on customer’s demands and the chosen materials. For any questions about surface treatment and enhancement, please do not hesitate to give us the message or email. We welcome for the discussion with you.

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia