Powder Bagging

| Item No.: | 03-30-100-2 |

Supplier Details

Country: Taiwan

City: Tainan City

Address: No. 41, Aly. 43, Ln. 94, Sec. 4, Anhe Rd., Annan Dist.

TEL: +886-6-3557878

Fax: +886-6-3561893

Online Showroom:

50 Products

Essentials for filling pellets into carry-on bag

1. Adopt Japan TOPACK combined palm type vertical filling and packaging machine, longitudinal sealing and sealing after completion of the horizontal sealing, and then cutting the aluminum foil package.

2. The pellets feeding is smoothed with a food-grade brush. The special measuring cup design ensures that the pellets are not damaged by mechanical force and the weight deviation is within 5%.

3. This machine is equipped with a static elimination device to reduce the electrostatic reaction generated when pellets are fed, which is beneficial for filling. However, the smaller the pellet size, the higher the static electricity generated. For the first mass production, it is necessary to prepare 500g of the pellet sample to test whether the machine can operate normally.

4. It can be properly vented to reduce the proportion of air in the aluminum foil and improve product stability.

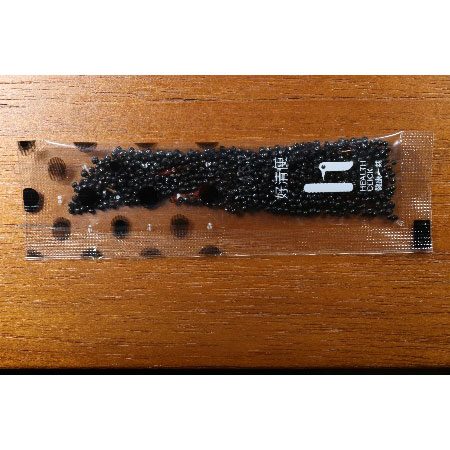

5. The sample photo is made of transparent aluminum oxide.

6. Specifications 2g~2.5g/package, aluminum foil finished product size 3cmx10cm

7. Daily production capacity: 30,000 bags

1. Adopt Japan TOPACK combined palm type vertical filling and packaging machine, longitudinal sealing and sealing after completion of the horizontal sealing, and then cutting the aluminum foil package.

2. The pellets feeding is smoothed with a food-grade brush. The special measuring cup design ensures that the pellets are not damaged by mechanical force and the weight deviation is within 5%.

3. This machine is equipped with a static elimination device to reduce the electrostatic reaction generated when pellets are fed, which is beneficial for filling. However, the smaller the pellet size, the higher the static electricity generated. For the first mass production, it is necessary to prepare 500g of the pellet sample to test whether the machine can operate normally.

4. It can be properly vented to reduce the proportion of air in the aluminum foil and improve product stability.

5. The sample photo is made of transparent aluminum oxide.

6. Specifications 2g~2.5g/package, aluminum foil finished product size 3cmx10cm

7. Daily production capacity: 30,000 bags

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt