Blow Film Extrusion-3

| Item No.: | 3-3 |

Supplier Details

Country: Taiwan

City: New Taipei City 231

Address: No. 17, Ln. 42, Baoxing Rd., Xindian Dist.

TEL: +886-2-29181558

Fax: +886-2-29188158

Online Showroom:

40 Products

Screw & Barrel for Blow Film High Speed Extrusion Design- 55mm

High-speed extrusion Screw and Barrel for film blowing

Applicable plastics: HDPE, LDPE, LLDPE, MDPE, PP, NYLON

Eco-friendly plastics: PLA, PVA

The quality and functional requirements are relatively high for the High functional plastic film. Sometimes it needs multi-layer co-extrusion to achieve the functional requirements.

In the field of multi-layer extrusion, the stability of feeding pressure and temperature, as well as the uniformity and light transmittance of product mixing are extremely high. Under this requirement, the relative degree of screw and barrel design will directly and seriously affect the extrusion quality.

In our experience,

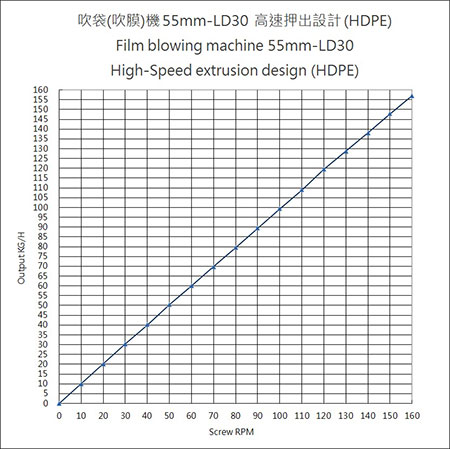

55mm film blowing extruder machine, motor configuration 40KW, the production capacity of extruding HDPE can reach about 140kg/H

Enlarging the motor can effectively increase the extrusion capacity

For blown film extrusion, which has extremely high requirements for extrusion production, mixing, stability, and service life, the most important key component is the screw and barrel.

Since 1989, we have been committed to the design and manufacture of high-capacity, high-mixing, high-speed screw and barrel with no temperature rise.

High-speed extrusion Screw and Barrel for film blowing

Applicable plastics: HDPE, LDPE, LLDPE, MDPE, PP, NYLON

Eco-friendly plastics: PLA, PVA

The quality and functional requirements are relatively high for the High functional plastic film. Sometimes it needs multi-layer co-extrusion to achieve the functional requirements.

In the field of multi-layer extrusion, the stability of feeding pressure and temperature, as well as the uniformity and light transmittance of product mixing are extremely high. Under this requirement, the relative degree of screw and barrel design will directly and seriously affect the extrusion quality.

In our experience,

55mm film blowing extruder machine, motor configuration 40KW, the production capacity of extruding HDPE can reach about 140kg/H

Enlarging the motor can effectively increase the extrusion capacity

For blown film extrusion, which has extremely high requirements for extrusion production, mixing, stability, and service life, the most important key component is the screw and barrel.

Since 1989, we have been committed to the design and manufacture of high-capacity, high-mixing, high-speed screw and barrel with no temperature rise.

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt