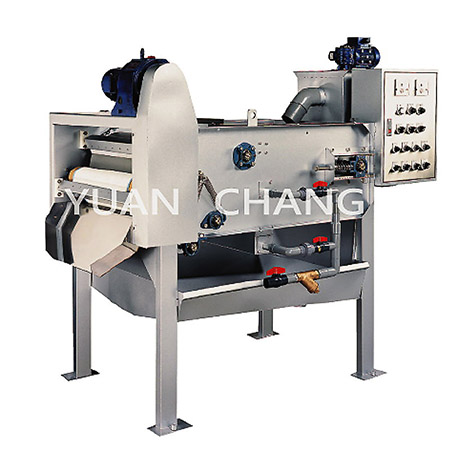

Belt Filter Press

| Item No.: | TD1 / TD2 Series |

TD1 (Conditioning + Single Belt Dewatering Type)

TD2 (Conditioning + Double Belt Dewatering Type)

1. Structure and Principle

The suitable polymer solution and the concentrated slurry dosed or pumped from the polymer solution storage tank and the slurry storage tank into the mixing tank to form the thickened sludge, then fall down the gravity--dehydrating zone evenly, then to form the sludge cake and come out by the scrapper.

2. Purpose (for TD1/TD2 Series)

For the sludge dewatering of the municipal waste water (city mixed raw sewage)、textile waste water、printing/dyeing sewage、chemical industry waste water、pharmacy waste water、paper & pulp sewage、leather & tannery sewage、livestock sewage、aquaculture sewage wine-making waste water、food waste water、metal-processing waste water、garbage buried plant waste water…and the other relative industries waste water…etc. waste water treatment plant.

3. Features (for TD1/TD2 Series)

- Filter belt: with good permeability and resistance to chemicals, with long life span when used normally.

- Stop & alarm device when abnormal deflection on filter belt.

- Input the concentrated sludge into our belt press (with thickening and dewatering function) to get the sludge cake and then have the next step- post-treatment incineration or being buried.

- With thickening and dewatering function for the various slurry dewatering treatment.

- With automatic control operating and continuous production for the various Slurry Dewatering Treatment.

- With easy washing, reasonable water consumption and not clogging easily of our Filter- Belt and its Washing System.

- With continuous treating and high working efficiency.

- With half-close structure / easy maintenance and lower horse power consumption/ lower noise.

- With light volume or weight-suitable for the installation of compact plant.

- With the simple operation, easy understanding / learning for the operator.

4. Specification and Functions (for TD1 / TD2 Series)

- The filter belt type press of the belt press had the polymer solution and slurry feeding, mixing, reaction with the stable flow condition from the polymer solution and slurry inlet to the sludge cake outlet.

- The polymer solution and slurry inlet to the mixing tank, via enough time agitating to make into a suitable sludge-flocs in our mixing tank.

- The sludge-flocs inlet to the gravity-dehydrating zone for gravity-dehydrating.

- The Sludge-flocs inlet to the wedge zone, then low pressure dehydrating high pressure dehydrating for removing the free water of the sludge-flocs and get the thickened sludge by widthways waves movement.

- The sludge cake come out by the scrapper.

- The solid content's rate of the sludge cake can reach about 15~25% (depends on the slurry feature)

Specification:

| Model Spec. | TD1-500K | TD1-500 | TD1-750 | ||

| Belt width (mm) | 500 | 500 | 750 | ||

| Treating capacity (m³/hr) Inlet consistency (S.S 1.5~2.5%) | 0.1~0.5 | 0.1~0.7 | 0.3~1.1 | ||

| Dried sludge D.S.(kg/hr) | 1.5~8 | 1.5~11 | 4.5~17 | ||

| Power consumption (HP) | Driving motor (fixed speed) | 1/4 | 1/2 | 1/2 | |

| Conditioning agitator motor | 1/4 | 1/4 | 1/4 | ||

| Reference machine dimensions (mm) | L | 1680 | 1830 | 1830 | |

| W | 950 | 1050 | 1300 | ||

| H | 1300 | 1650 | 1650 | ||

| Base dimensions (mm) | L1×W1 | 880×750 | 1110×850 | 1110×1100 | |

| Reference weight (kgs) | 280 | 430 | 520 | ||

| Model Spec. | TD2-500 | TD2-750 | TD2-1000 | ||

| Belt width (mm) | 500 | 750 | 1000 | ||

| Treating capacity (m³/hr) Inlet consistency (S.S 1.5~2.5%) | 0.2~1.4 | 0.5~2.0 | 0.8~2.8 | ||

| Dried sludge D.S.(kg/hr) | 3~21 | 7.5~30 | 12~42 | ||

| Power consumption (HP) | Driving motor (fixed speed) | 1/2 | 1/2 | 1/2 | |

| Conditioning agitator motor | 1/4 | 1/4 | 1/4 | ||

| Reference machine dimensions (mm) | L | 1830 | 1830 | 1900 | |

| W | 1050 | 1300 | 1550 | ||

| H | 1900 | 1900 | 1900 | ||

| Base dimensions (mm) | L1×W1 | 1110×850 | 1110×1100 | 1110×1350 | |

| Reference weight (kgs) | 390 | 470 | 580 | ||

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia