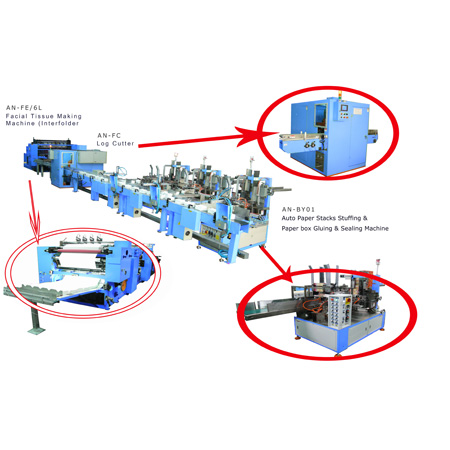

Tissue Production Machine

| Item No.: | AN-42633E/4L~6L + AN-64320 + AN-83646A |

Supplier Details

Country: Taiwan

City: New Taipei City 24257

Address: No. 43, Jianguo 1st., Rd., Xinzhuang Dist.

TEL: +886-2-29085266

Fax: +886-2-29086355

Online Showroom:

51 Products

Automatic Facial Tissue Making Machine

Character:

Options:

Log Cutter for Hand Towel/Facial Tissue Making Machine

Auto Paper Stacks Stuffing & Paper Box Gluing & Sealing Machine

MODEL: AN-BY01

| Model No. | AN-42633/3L + AN-42633E/3L | AN-42633/4L + AN-42633E/4L | AN-42633/5L + AN-42633E/5L | AN-42633/6L + AN-42633E/6L |

| Sheet size | 210(L) x 180~215(W)/mm The width is adjustable at 5mm progressive changes. | |||

| Folded size | 105(L) x 180~215(W)/mm | |||

| Folding shape | Interfold | |||

| Speed (sheet/min.) | 2400~3600 | 3200~4800 | 4000~5250 | 4800~6000 |

| Varied by terms & conditions | ||||

| Converting web | 2-ply facial tissue, 13gsm~14.5gsm x 2 ply. | |||

| Jumbo roll width (mm) | 540~645 | 720~860 | 900~1075 | 1080~1290 |

| Jumbo roll stand | 2 pcs | |||

| Jumbo roll dia. | 1500mm φMax | |||

| Compressed air | Air source 6 kg/cm2 | |||

Character:

- With one unit of embossing device (only for AN-FE):

Steel Roller x 2 pcs & Rubber Roller x 2 pcs

It to be charged extra if the embossing pattern is special. - Web tension control by manual.

- With driving belt for jumbo roll.

- The jumbo roll could be colored, thus increasing fun for users.

- Cutting tools are changed easily only screws adjustment is required.

Options:

- Steel to steel embosser: Steel Roller x 4 pcs

Also could add Gluing laminination * 1 set - Printing device: one color printing device: including 2 sets of printer

Log Cutter for Hand Towel/Facial Tissue Making Machine

| Model No. | AN-FC |

| Cutting Speed | 120 cuts/mm ( 200mm) |

| Delivery | 1 (lane) |

| Cutting knife | 610mm. |

| Control | Human Machine Interface |

| Conveyor | 2 pcs |

Auto Paper Stacks Stuffing & Paper Box Gluing & Sealing Machine

MODEL: AN-BY01

| Box size | (A)200~260(L) x110~120(W) x 45 ~110(H)/mm (approx) | ||||

| (B)140~190(L) x110~120(W) x 45 ~110(H)/mm (approx) | |||||

| Card Board Box material | (A) Box height below 80mm: 350 gsm | ||||

| (B) Box height over 80mm: 400 gsm | |||||

| Box pusher | Extra long pushers are required if box height over 90mm | ||||

| Adhesive material | Mot Melt Glue | ||||

| Speed | (A)32-40 boxes/min. | ||||

| (B)35-40 boxes/min. | |||||

| Heater | 500W x 6 pcs | ||||

| Air Consumption | By 3~5 HP air compessor (Excluding in quotation). | ||||

- Box Standby Supporter.

- Gluing & Sealing Device.

- Cylinder to push forward Stack of finished boxes.

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia