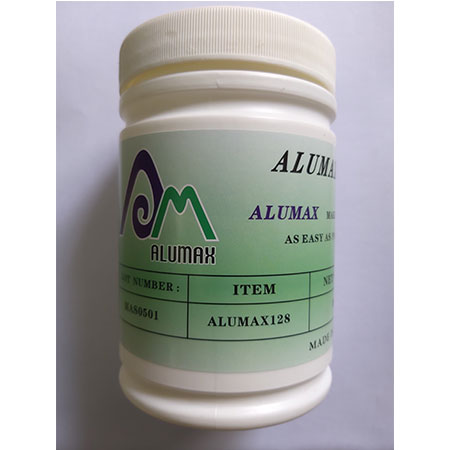

Aluminum Flux

| Item No.: | Alumax |

Supplier Details

Country: Taiwan

City: Chiayi City 600

Address: 1F., No. 33, Guangzhou St., West Dist.

TEL: +886-5-2852137

Fax: +--

Online Showroom:

39 Products

Welding flux

Alumax

Directions

•First steps:

Base metals should be cleaned thoroughly to remove the surface dirt, grease and other impurities

Cleaning heavily oxidized surfaces may be applied other methods such as steam jet, wire brushing, or mechanical grinding

•Seconds steps:

Heat the end of filler metal rod and dip into flux, or sprinkle flux on work-piece, or can be mixed with water or methyl, ethyl or isopropyl alcohol to form a paste

•Third steps:

Continue heating until the flux liquefies and flows then fills the joint, producing shiny fillets

The flux wets the joining surfaces thoroughly and prevents the aluminum oxide inclusions in the joints

TYPICAL APPLICATIONS

• Aluminum water tank

• Inter cooler

• The evaporator of parallel flow condenser

• Laminated evaporator

• Oil cooler

Specification

• AWS A5.31 FB1A, AMS 3412.

Alumax

Directions

•First steps:

Base metals should be cleaned thoroughly to remove the surface dirt, grease and other impurities

Cleaning heavily oxidized surfaces may be applied other methods such as steam jet, wire brushing, or mechanical grinding

•Seconds steps:

Heat the end of filler metal rod and dip into flux, or sprinkle flux on work-piece, or can be mixed with water or methyl, ethyl or isopropyl alcohol to form a paste

•Third steps:

Continue heating until the flux liquefies and flows then fills the joint, producing shiny fillets

The flux wets the joining surfaces thoroughly and prevents the aluminum oxide inclusions in the joints

TYPICAL APPLICATIONS

• Aluminum water tank

• Inter cooler

• The evaporator of parallel flow condenser

• Laminated evaporator

• Oil cooler

Specification

• AWS A5.31 FB1A, AMS 3412.

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt