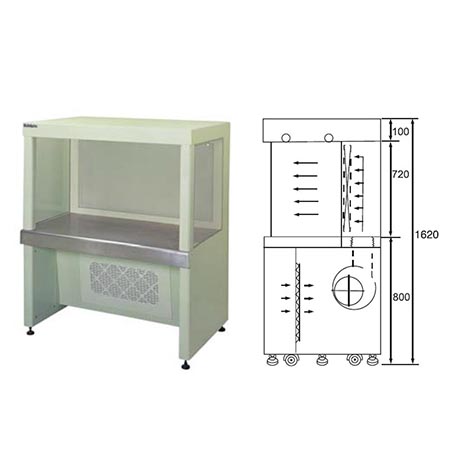

Horizontal Flow Clean Bench

| Item No.: | HF1350/ HFS1350/ HF1900/ HFS1900 |

Supplier Details

Country: Taiwan

City: Taipei City

Address: Rm. 4, 7F., No.160, Sec. 6, Minquan E. Rd., Neihu Dist.

TEL: +886-2-27946262

Fax: +886-2-27914710

Online Showroom:

71 Products

Clean Bench – Horizontal Flow

A Clean Bench system is a vital concept in the control of particulate contamination. Clean Bench is defined as air moving at the same speed and in the same direction, with no or minimal cross-over of air streams. Horizontal Clean Benches direct HEPA-filtered air horizontally over the work area to provide ISO Class 5 (formerly Class 100) conditions and protect your work from particulate contamination. Applications for clean benches include plant tissue culture; media plate preparation, electronics inspection, medical device assembly and pharmacy drug preparation. Table Separate Type (HFS) is optional to anti-Vibration of desk top.

Clean bench is the use of efficient air purification unit, a higher level of manufacturing clean area for low level clean room, local work environment cleanliness requirements of the higher places; it can save a lot of initial investment and operating costs.

With professional technology design, and manufacture of new vertical unidirectional flow clean bench, this device is widely used in photoelectric prompt, microelectronics, aseptic packaging, food, medical equipment, pharmaceuticals, clean paint and other industries.

Application: Medicine and health, bio-pharmaceuticals, food, medical science study, optics, electronics, sterile lab, sterile microbiological testing, plant tissue culture, other scientific environment and producing dept.

Specification of HF1350/ HFS1350

Brand name: Air System

Standard Outer Dim.: 1350*800*1620 (WxDxH)

Standard Inter Dim.: 1250*650*700 (WxDxH)

Material: Powder Backed epoxy steel (ivory) or SUS304 stainless steel

Air Velocity: 0.4~0.6m/s

Power Supply: 1Ø 110V/220V 50/60HZ, 375W

HEPA Filter: 600*1210*70mm

Pre Filter: 400*625*25mm

Fluorescent Light: 30W*2pc

UV Lamp: 15W*2pcs(optional)

Accessories: Socket, Switch, Diff Pressure Gauge Timer

Prompt delivery time

Sizes and designs can be customized

Origin: Design and manufacture in Taiwan

A Clean Bench system is a vital concept in the control of particulate contamination. Clean Bench is defined as air moving at the same speed and in the same direction, with no or minimal cross-over of air streams. Horizontal Clean Benches direct HEPA-filtered air horizontally over the work area to provide ISO Class 5 (formerly Class 100) conditions and protect your work from particulate contamination. Applications for clean benches include plant tissue culture; media plate preparation, electronics inspection, medical device assembly and pharmacy drug preparation. Table Separate Type (HFS) is optional to anti-Vibration of desk top.

Clean bench is the use of efficient air purification unit, a higher level of manufacturing clean area for low level clean room, local work environment cleanliness requirements of the higher places; it can save a lot of initial investment and operating costs.

With professional technology design, and manufacture of new vertical unidirectional flow clean bench, this device is widely used in photoelectric prompt, microelectronics, aseptic packaging, food, medical equipment, pharmaceuticals, clean paint and other industries.

Application: Medicine and health, bio-pharmaceuticals, food, medical science study, optics, electronics, sterile lab, sterile microbiological testing, plant tissue culture, other scientific environment and producing dept.

Specification of HF1350/ HFS1350

Brand name: Air System

Standard Outer Dim.: 1350*800*1620 (WxDxH)

Standard Inter Dim.: 1250*650*700 (WxDxH)

Material: Powder Backed epoxy steel (ivory) or SUS304 stainless steel

Air Velocity: 0.4~0.6m/s

Power Supply: 1Ø 110V/220V 50/60HZ, 375W

HEPA Filter: 600*1210*70mm

Pre Filter: 400*625*25mm

Fluorescent Light: 30W*2pc

UV Lamp: 15W*2pcs(optional)

Accessories: Socket, Switch, Diff Pressure Gauge Timer

Prompt delivery time

Sizes and designs can be customized

Origin: Design and manufacture in Taiwan

English

English

中文繁體

中文繁體 Русско

Русско Deutsch

Deutsch Español

Español Português

Português Français

Français Türk

Türk Italiano

Italiano Nederlands

Nederlands हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia